The basis for your success in the welding sector is powerful, precise and robust laser welding systems.

AL

AL series lasers are extremely flexible when it

comes to power, laser source and equipment. The

AL can therefore be individually configured and

optimally adapted to changing requirements. AL series devices work excellently with AL-T

workbenches. However, you can also integrate the AL into your

existing machine assembly. Nd:YAG laser sources

are available with 75 to 500 watts of power. Your

advantage: The laser power actually gets to the

workpiece. These compact laser welding devices can even

perform very fine welding tasks. The cooling system

is integrated into the laser on all devices.

However, the AL 500 requires additional external

cooling.For all technical details, please refer to the data sheet.

AL-CROSS

Its housing is robust with sturdy aluminum

handles that provide shock protection for edges

and housing and supports the easy movement

of the system. There are integrated eyelets for

loading and stowing, plus a hook for a winch. User-oriented are the generous storage areas for

this and that, as well as the specially designed

holders that can be fixed to the hole pattern on

the sides of the welding laser to accommodate

welding wire, joystick, the foot pedal, safety

glasses and tools. The 5th wheel on the laser

enables the direct transport of the gas bottle,

which is extremely practical. The AL-CROSS is mobile thanks to its easily

movable wheels. It fits through standard doors

and with its transport height of 1.25 m (display

can be tilted) into every small van with a loading

height of at least 1.40 m. And the best way to experience the mobility of the arm, the lenses

and the laser head is to try it out! The fiber laser is powerful, because 450 W/600 W

constant laser power are waiting for use. Welding

is either pulsed or in CW mode. The welding

behaviour can be influenced via integrated pulse

shapes. The parameters are set either via the

colour display or via the multifunction footswitch

or the new AL-DRIVE control unit. The display is titlable (orientable) in order to

always have an optimal view and an integrated

keyboard is within easy reach of the operator.For all technical details, please refer to the data sheet.

AL-IN

The AL-IN is available with the Nd:YAG laser

sources 150 W or 200 W. Standard is a fixed

objective with 150 mm focal length. Optionally,

the turn and tilt objective or the perpendicular

objective with LED ring light is possible, too.

The 200 W laser provides a connection for an

unregulated, external cooling. The movement system is operated via a novel

control box. This control box is mounted on top of

the supply unit of the laser AL. The welding process

is usually done with a joystick but can also be

carried out semi-automatic or fully automatically. The work pieces can be positioned in front of the

movement system, either on a worktable or directly

on the pallet truck.Optionally a tabletop is available.For all technical details, please refer to the data sheet.

AL-TW

The AL-TW laser system can be equipped with

300, 450, 600 or 900 W laser sources. The laser

source is integrated into the work bench. With

the modular device concept, you can also use a

wide range of objectives and focal distances, optimally

adapted to your special welding jobs. The open AL-TW system allows welding of

the largest and smallest workpieces, without

limitation. Whether deposition welding, repairs, series

production, medical technology components or

sensors, we offer you the right laser performance

and plenty of accessories. If your needs change

later, you can upgrade the 300 and 450 Watt models

to double the performance. The laser and movement system are easily operated

from a side console with an intuitive touch

screen. You can choose to weld manually with

the quick-reacting joystick, semiautomatically or

automatically with WINLaserNC software.For all technical details, please refer to the data sheet.

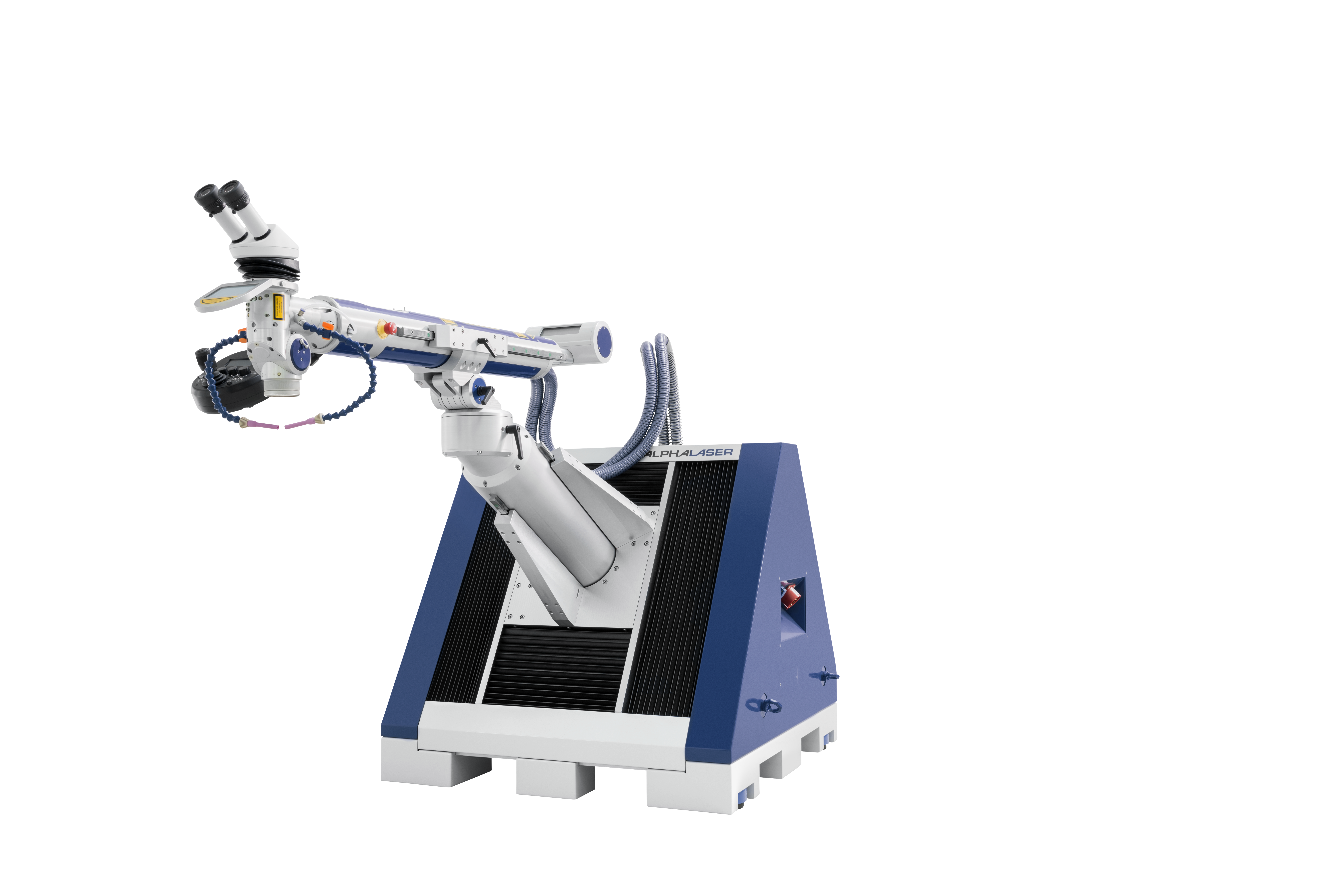

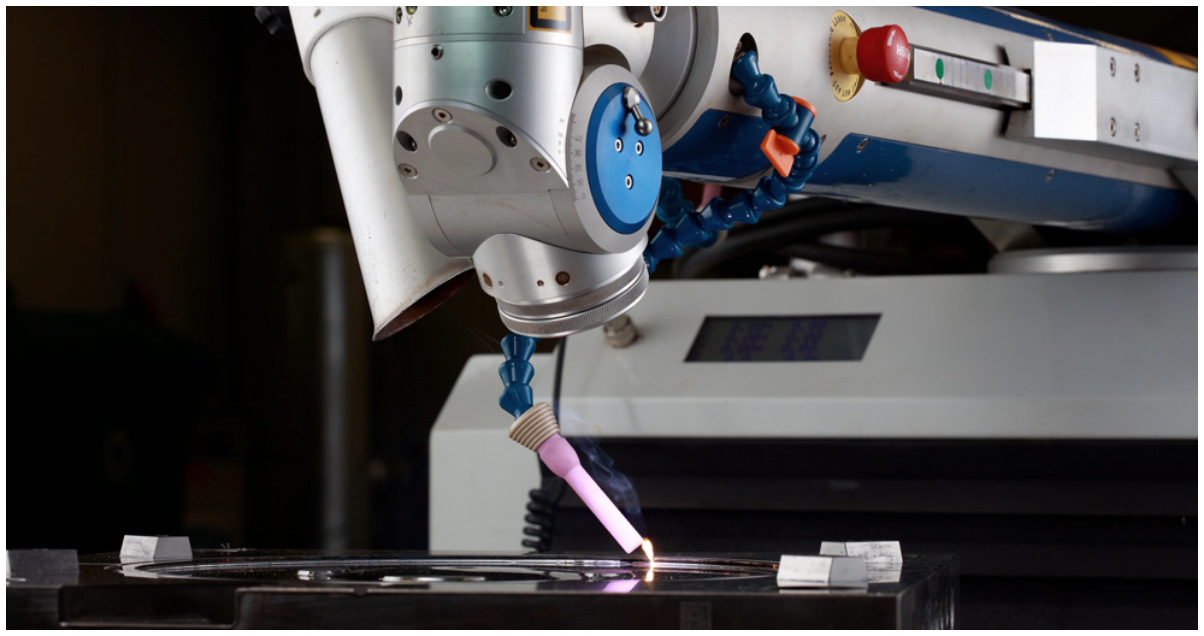

ALFlak

The ALFlak’s laser arm projects a great distance

to effortlessly reach its welding position, even

in deep or complex molds. Welding seams up to

500 mm are possible without relocation. Your

advantage: The welding process can be performed

without constant repositioning. The ALFlak comes in two versions: with a self-propelled

caterpillar track or a model that can be

moved manually. Choose the laser source that fits your requirements:

You can choose Nd:YAG 200 W or 300 W

laser sources or fiber lasers with output of 300,

450, 600 or 900 W. If your needs change later, you can equip your

ALFlak with a 300 W or 450 W fiber source to

double the output.For all technical details, please refer to the data sheet.

ALFlak F

The ALFlak’s laser arm projects a great distance

to effortlessly reach its welding position, even

in deep or complex molds. Welding seams up to

500 mm are possible without relocation. Your

advantage: The welding process can be performed

without constant repositioning. The ALFlak comes in two versions: with a self-propelled

caterpillar track or a model that can be

moved manually. Choose the laser source that fits your requirements:

You can choose Nd:YAG 200 W or 300 W

laser sources or fiber lasers with output of 300,

450, 600 or 900 W. If your needs change later, you can equip your

ALFlak with a 300 W or 450 W fiber source to

double the output.For all technical details, please refer to the data sheet.

ALFlak 500

Finally, united – this is how you can summarize

the great customer value of the new ALFlak 500

in short words. By integrating the 500 W laser

into the ALFlak housing, mobility has been significantly

increased and the system with caterpillar

tracks can be loaded by just one person. The laser source with 500 W average power

always has enough reserves for demanding welding

tasks. The high laser power delivers 15 kW

peak power and effortlessly melts large welding

wire diameters. The welding speed is significantly

higher, so that you can do a large amount of welding

in a short time and with the best connection

to the base material. The laser and the motion system are comfortably

operated via the intuitive 10" touch screen (15"

as option). In addition, the laser parameters can

be set or adjusted during welding by using the

patented multifunction footswitch. This allows

full concentration on the welding task without

having to take your hands off the workpiece. Programming

the WINLaserNC software is also done

directly on the touch screen. This system uses a new power supply technology.

The power supply is water-cooled and

current-controlled, thus preserves the laser lamp. For cooling, an external 18 kW cooler is needed.

However, smaller welding tasks can also be performed

without a cooler. A 230 V power outlet is integrated in the laser

sytem, so you can connect e.g. the external extraction

directly to the device. In addition, the laser device meets the high safety

requirements for performance level d.For all technical details, please refer to the data sheet.

ALFlak Max

With a laser arm almost 2.80 m long, the ALFlak

MAX offers an especially large movement radius–

as a service provider or mold maker, this

gives you even more flexibility for your applications.

Whether working on pressing tools, large

molds or machine components, just move the

ALFlak MAX on its self-propelled caterpillar track

to the workpiece, aim the laser arm at the weld,

and start welding. Welding seams up to 340 mm

are possible without relocation. A rotatable laser head, the unique optional turn

and tilt objective, and various focusing lenses ensure

that you can reach almost any position on

the workpiece with the laser beam. The ALFlak

MAX comes in two versions: with a self-propelled

caterpillar track or a model that can be moved

manually. The User Coordinate Controller offers additional

ease of use for effortlessly teaching in a slope as

a work surface.For all technical details, please refer to the data sheet.

ALM

Extremely short set-up times allow a vast range

of machine components, pressing tools and large

molds to be repaired and modified with the ALM

at any imaginable location. The ALM’s versatility is impressive. The workpiece

can be transported to the laser, or the laser

to the workpiece. This ensures mobility within

the company or at the customer’s. The ALM is air cooled and requires no additional

cooling system. Just move the laser to the workpiece,

secure the laser area, aim the slim laser

arm at the weld, and start welding. The hydraulic brakes fix the laser beam exactly at

the desired work position. Welding can be done

manually using a joystick, semi-automatically, or

using an external operating unit. Additional flexibility is possible with the unique

turn and tilt objective, which allows the laser

beam to be moved continuously up to 40° from

vertical to any direction.For all technical details, please refer to the data sheet.

ALO

If you want to weld long or bulky parts quickly,

manually and flexibly, if you are looking for a

simple load and want to work in the shielded

laser safety area, the ALO is the ideal device for

you. The working chamber can be loaded via various,

laser-safe openings: Through lateral slots you can

position longer components in the processing

room and then weld them in a laser-safe manner.

Another passage at the bottom of the working

chamber also allows loading from below. At the

front, a large opening ensures easy access to the

spacious welding chamber. The laser-proof leather

curtain offers laser protection so that the ALO can

be placed in any work environment. The armrest is extremely comfortable - thus ensuring

relaxed work. Again, we have paid much

attention to a good ergonomics.With the ALO 100 we offer 100 W output power

and 25 Hz pulse frequency available and with the

ALO 120 even 120 W and 50 Hz, so you can use

this model additionally for laser polishing. The possibility to connect an external cooling system

allows high frequency operation over a long

period of time.For all technical details, please refer to the data sheet.

ALV

The compact and ergonomic ALV welding laser

with a laser-safe working chamber is available

with different laser powers, laser sources and

with app or NC control. The ALV is used in the areas of precision and

deposit welding in the tool and mold sector, in

sensor production and in medical and precision

engineering. The welding machine offers a large height travel

and doors that can be opened wide, so that even

larger workpieces can be accommodated. For sensor applications, upward-opening wing

doors with a side slot can be ordered for easy positioning

of long tubes. A fine welding function

reduces the spot diameter to 0.1 mm. The ALV has 3 linear axes of movement, with the

vertical Z-axis lifting up to 50 kg. Different axes

of rotation for machining cylindrical parts are optionally

available. The machine version with WINLaserNC control

enables interpolated driving in XYZ for automated

welding such as the processing of magazines

with several components. The laser system is operated via an intuitive

touchscreen. In just a few steps, the laser-safe, closed system

can be turned into an open laser workstation,

for which of course appropriate laser protection

measures must be taken. The ALV meets the high security requirements

for performance level d.For all technical details, please refer to the data sheet.

ALV F

The compact and ergonomic ALV welding laser

with a laser-safe working chamber is available

with different laser powers, laser sources and

with app or NC control. The ALV is used in the areas of precision and

deposit welding in the tool and mold sector, in

sensor production and in medical and precision

engineering. The welding machine offers a large height travel

and doors that can be opened wide, so that even

larger workpieces can be accommodated. For sensor applications, upward-opening wing

doors with a side slot can be ordered for easy positioning

of long tubes. A fine welding function

reduces the spot diameter to 0.1 mm. The ALV has 3 linear axes of movement, with the

vertical Z-axis lifting up to 50 kg. Different axes

of rotation for machining cylindrical parts are optionally

available. The machine version with WINLaserNC control

enables interpolated driving in XYZ for automated

welding such as the processing of magazines

with several components. The laser system is operated via an intuitive

touchscreen. In just a few steps, the laser-safe, closed system

can be turned into an open laser workstation,

for which of course appropriate laser protection

measures must be taken. The ALV meets the high security requirements

for performance level d.For all technical details, please refer to the data sheet.

ALW

The ALW is a comfortable, ergonomic seated

workstation that offers plenty of legroom. The observation

optics offer a variable viewing angle in

the range 10°-50° and thus enables comfortable

working while sitting or standing. Demanding materials such as aluminum, copper

alloys, precious metals, titanium and sensitive

alloys can be easily welded with the powerful

ALW 200/300. With the optional fine welding

function, you can reduce the spot diameter to

˂ 0.1 mm. This welding laser is ideally suited for series production.

The NC software is integrated. Programming

and teaching takes place directly on the

12.1“ touchscreen display. Additional I/Os are

also available. In addition, an automatic wire feeder.

For toolmaking tasks, the functions „UCS“

(user coordinate system) and „individual teaching“

are very helpful.For all technical details, please refer to the data sheet.

ALW F

The ALW is now also available in the version fiber

laser with 300 W and 450 W laser power. The fiber

source has a high energy efficiency and is ideally

suited for reproducible welding because the

laser power is monitored during the welding process.

Welding can be done in CW mode or pulsed. The ALW is a comfortable, ergonomic and compact

seat workplace that offers plenty of legroom

and can be adjusted to the size of the operator

thanks to the height and forward adjustable foot

plate. The observation optics offer a variable

viewing angle in the range of 10°-50° and thus

enables a comfortable work. The closed, laser-safe enclosure makes the ALW

a laser-protected workstation that can be used

in the normal production environment without

any additional safety precautions. We have again

reinforced the laser protection by metal lamellas

behind the bellows. In addition, the system meets

the high security requirements for performance

level d.For all technical details, please refer to the data sheet.

SL 50

The SL 50 is based on the successful ALS 35S. It is one of the fastest manual laser workstations on the market. With its maximum average power of 120 watts and the pulse frequency of 25 shots per second (optionally 50 Hz), the laser system is particularly suitable for series production.

Especially when welding seams, the processing time can be reduced to a minimum with this laser. For processing particularly small, filigree workpieces, the beam diameter can be reduced to 0.05 mm with the optional fine welding function. The housing consists of a high-quality welded stainless steel construction. Additional flexibility when processing larger workpieces is provided by the spacious, closed working chamber with removable base. For all technical details, please refer to the data sheet.

VLO 60

This desktop laser systems with 60 watts offers

a reliable beam behavior and stand out for its

consistent, powerful and yet soft welding behavior. The VLO 60 has a sheet metal housing with a large

opening at the front for easy and quick access to

the spacious working chamber. The armrest is

extremely comfortable - so relaxed work is guaranteed.

The laser-safe leather curtain offers laser

protection, so that the VLO 60 can also be placed

in any work environment. The work area is well lit and the light intensity can

be dimmed. A welding fume extractor is integrated

as standard. The laser welding device is operated conveniently

via a touch display. Even the finest joints can be made with the optional

micro welding function and monitored through

the stereo microscope. This table-top laser welding device is ideal for

dental laboratories, goldsmiths and manufacturers

of sensors and microcomponents, as well as

for anyone who wants to weld small components

quickly and easily by hand.For all technical details, please refer to the data sheet.